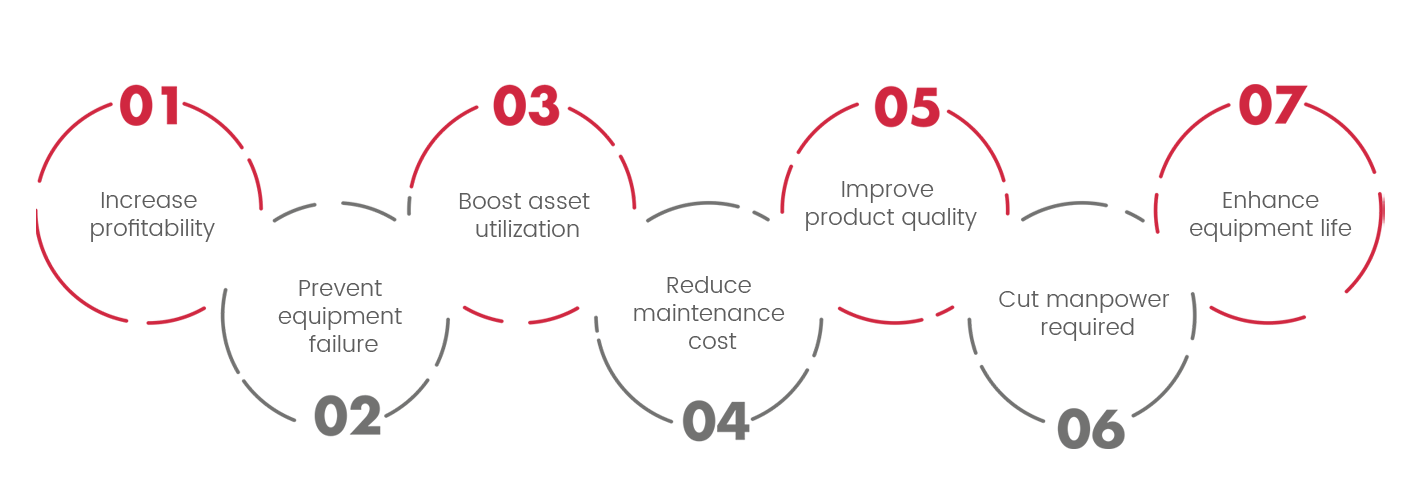

PREDICTIVE MAINTENANCE IS THE SOLUTION YOU NEED!

PREDICTIVE MAINTENANCE

The smart and path breaking operations strategy anticipating machine failures.

We employ remote sensors and advanced analytics to alert you about failures well in time.

DAWN OF A NEW ERA!

Transform the approach to factory operations. Predict and Prevent component failure to keep your equipment operating at peak capacity.

Go on! Predict the Unpredictable with AccuPredict!

What do we do?

We keep your equipment running by preventing unplanned failures. We do this by monitoring vibrations of key components 24X7 from a distance.

We alert you in time about impending failures and actions needed to restore condition.

How does it work?

A 5 step process

- Connect sensors to critical components

- Monitor vibration signals 24X7

- Analyse the trend

- Identify the cause and the MTBF

- Recommend corrective action needed

Why choose us?

- A passionate team with decades-long experience in delivering Predictive Maintenance.

- The proven approach of prediction is based on machine fundamentals, not simple pattern matching.

- Large base of loyal customers worldwide across verticals.

WITH EXPERIENCE OF OVER THREE DECADES IN THE FIELD, WE INVITE YOU TO JOIN US ON THE JOURNEY TO OPERATIONS EXCELLENCE!

HAPPY CUSTOMERS AROUND THE WORLD! THE LIST CONTINUES TO GROW!

CUSTOMER STORIES

AccuPredict’s solution has proven to be cost effective and energy efficient. It not only helped us eliminate some of our catastrophic equipment failures, but also extended the operational life of machine components and reduced the costs of parts and labor.

A catastrophic failure of Steam Turbine was avoided due to periodic Vibration Monitoring. Predictive Maintenance is so very important, and people just neglect it. Until and unless they start facing the actual problem, they do not understand its benefits.

We saved 7 days of production and had financial benefit of several Millions as a direct result of implementation of AccuPredict’s Predictive Maintenance solution. It also helped us identify assets and operational processes that were at the greatest risk of failure.

Predictive Maintenance has been our core competence for over three decades. Our demonstrated performance has earned us the loyalty of a customer base that cuts across industry verticals – Engineering, Power Generation, Chemical Process, Shipping, and Wind Power. We have customers around the World from India to the Middle East, Africa, Europe, and the USA. Over this period we have built a strong team of Engineers passionate about their work. They have deep technical expertise in the field of using vibration to predict equipment failure. Give us the opportunity to be your partner on the journey to operations excellence.

We are headquartered in Singapore with a significant presence in India.

Our Leadership

Milind Yedkar

CEO

Milind is a Chemical Engineer from Indian Institute of Technology, Bombay with an MBA from Indian Institute of Management, Ahmedabad. He has over forty years’ of business experience in Sales, Marketing and Operations at Fortune Global 50 Corporations like Procter and Gamble and Dell Technologies. During his career he has acquired a pan-Asia Pacific experience that comes out of living and working in India, Japan, China and Singapore.

Sanjay Deshpande

CTO

Sanjay has a degree in Mechanical Engineering from University of Pune and Technical University of Denmark. He also holds a Master’s Degree in Electronics. He has forty years’ experience running his own consultancy in Denmark and India offering Condition Based Monitoring (CBM) services to customers around the world.

Happy to Help

Contact us anytime if you want to know more about our services and solutions.